Model

BW-NIR-130

Sensor Type

CCD camera, contactless

Spectral Range

950-1100nm

Minimum Spot Size

130 µm

Focus Spot Size

130 µm to ~ 2.75 mm

Power Range

400 W to >100 kW

Minimum Power Density

15 kW/cm

Maximum Beam Diameter at Entrance/Exit

12.5 mm

Communication

GigE

CE Compliance

Yes

UKCA Compliance

Yes

China RoHS Compliance

Yes

Software

• Instantly measure focus spot size

BeamWatch utilizes disruptive technology to measure laser beam characteristics of very high power lasers. By not intercepting the beam and yet providing instantaneous measurements, you can now monitor the beam at frequent intervals without having to shut down the process or remove tooling and fixtures to get access. In addition, you can now measure focal spot location at several times per second and know if there is any focal spot shift during those critical start-up moments.

Disruptive Technology

BeamWatch is the first device to measure a laser without coming in contact with its beam which allows it to be the first laser quality measurement product in history to have no upper limit on the lasers which it can measure. BeamWatch provides high-power industrial laser users with data never before seen such as the dynamic measurement of focus shift caused by thermal effects on the laser system. BeamWatch also provides the industrial laser user with measurement of other key laser operating parameters in real-time.

The system measures the signal generated from Rayleigh scattering around the laser’s beam waist, where the power density is the highest. Rayleigh scattering is a physical property of light caused by light scattering off of air molecules. Unlike traditional beam measurement systems, the beam passes directly through BeamWatch and is not disrupted, mechanically or optically. In addition, BeamWatch has no moving parts so there is no need for cooling of any components. Specialized system software dynamically measures the signal multiple times per second, allowing the laser user to key in on critical operational laser attributes, such as beam waist size and position with respect to the material being processed.

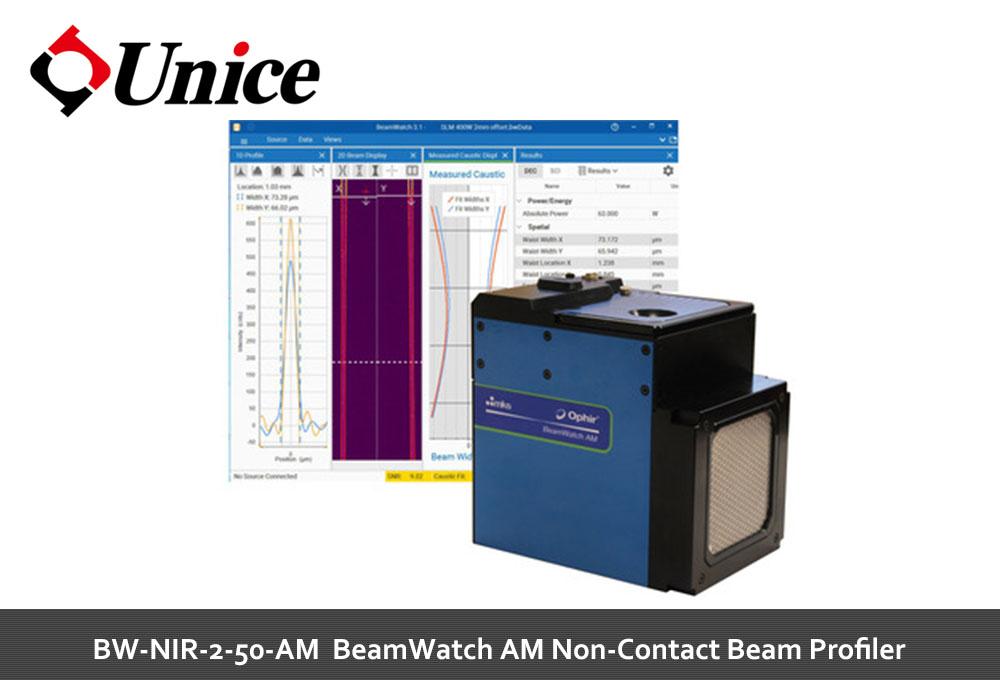

BeamWatch User Interface

The user has access to those tools needed for start-up and

Focus Spot Size (Waist Width)

BeamWatch images the full beam caustic measuring the waist at its smallest point, many times per second.

Focus Spot Location

Now you can precisely know the dynamic behavior of focal spot shift throughout the laser duty cycle. By inputting the known distance from the laser delivery head to a precise datum on BeamWatch the focal spot distance is constantly measured and tracked with millisecond updates.

Assured Process Consistency

Measure as often as needed to assure repeatable and consistent process uniformity. Mount BeamWatch into the process or manually insert BeamWatch and make periodic measurements.

Automation Interface

BeamWatch includes the tools to support Automation Clients written in Visual Basic for Applications (VBA), C++ CLI, or any .Net compliant environment, such as Microsoft Excel or National Instruments’ LabVIEW.

Software Features

Features Dual Axis

Results - Power/Energy Relative Power (Absolute Power when configured with Juno and an Ophir Power Meter)

Results - Spatial Waist Width X & Y

Waist Location X & Y

Focal Shift X & Y

Centroid X & Y

Width at Cursor X & Y

Ellipticity at Curso

Rayleigh Length X & Y

Width at Cursor X & Y

Results - Beam Quality M2 X & Y

M2 Average

K X & Y

K Average

BPP X & Y

BPP Average

Divergence X & Y

Divergence Average

Results All results can be shown/hidden.

Frame Info Frame ID

Timestamp

1D Profile Logarithmic or Linear

Control to enable/disable the beam width markers

Profiles are drawn at the cursor location. Cursor is controlled in the 2D display

Display shows current cursor location and width at cursor results

The X and Y profiles are overlapped in a single display

2D Beam Display Overlays that can be enabled/disabled

Fitted caustic and drawn beam area

Raw data points

Beam Image

Alignment Crosshair – Marks the center of the display for each axis

Beam can be displayed vertically or horizontally on the screen

Labels indicate X and Y axis and the direction of beam propagation

Cursor can be moved to any point along the beam

Focal point indicators – one shows current waist position, another shows first found waist position

Statistics Mean, Std Dev, Max, Min, and Sample Size

System Requirements PC computer running Windows 7 (64) and Windows 10 Laptop or Desktop:

GHz Pentium style processor, dual core recommended

Minimum 2GB RAM

Accelerated Graphics Processor

Hard drive space suitable to hold the amount of video data you expect to store (50-100 GB recommended)

BeamWatch® & BeamWatch®Plus Non-contact, M2,Focus Spot Size and Position Monitor for high power NIR and VIS lasers

BeamWatch utilizes disruptive technology to measure laser beam characteristics of very high power lasers. By not intercepting the beam and yet providing instantaneous measurements, you can now monitor the beam at frequent intervals without having to shut down the process or remove tooling and fixtures to get access. In addition, you can now measure focal spot location at several times per second and know if there is any focal spot shift during those critical start-up moments.

BeamWatch®Plus

The BeamWatch®Plus is capable of measuring both NIR and VIS high-power lasers with small focal spots while the BeamWatch® designated for high-power lasers with larger focal spots at NIR.

Measuring Focal Shift with BeamWatch

Focus Shift Monitoring of High Power Laser

VIDEO

VIDEO

Is your laser's focus spot where you think it is? This video shows the focal shift of a 100 Kw laser during the first four seconds of startup using BeamWatch, Ophir's non-contact high power beam analyzer.

BeamWatch™ utilizes disruptive technology to measure very high power YAG and fiber lasers. By not intercepting the beam and yet providing instantaneous measurements, you can now monitor the beam characteristic at frequent intervals without having to shut down the process or remove tooling and fixtures to get access. In addition, you can now measure focal spot location at millisecond intervals and know if there is any focal spot shift during those critical start-up moments.

BeamWatch Dynamically Measures 100kW Fiber Laser

Laser Measurement Solutions for High Power Industrial Laser Applications

VIDEO

VIDEO

The BeamWatch® industrial beam profiling system provides data that has never been seen or measured, even to laser users that have been working with high-power lasers for years. Through the dynamic measurement of beam waist location, the laser engineer can know how changes in power density affect the quality the process. For example, data is now available about the laser’s effect on the quality and consistency of laser welds, cuts, and holes drilled.

Modern production facilities must constantly increase throughput, at less cost, with less scrap, and with minimum downtime. In this video overview, you will learn how application of new, advanced technology in measurement devices, can help both designers and users of industrial laser systems to optimize and control their processes, so they can accomplish these goals and achieve consistently good results – both in quality and quantity.